Introduction: Ultrasonic welding has emerged as a revolutionary technique in the manufacturing industry, offering a fast, efficient, and precise method for joining materials. Below we delve into the history of ultrasonic welding, its applications in manufacturing, and the value it brings to various industries.

History of Ultrasonic Welding:

Ultrasonic welding traces its roots back to the early 1960s when it was first introduced as a viable welding method. Developed as a solid-state welding process, ultrasonic welding utilizes high-frequency vibrations to generate heat at the weld interface, allowing materials to bond seamlessly. Over the years, advancements in technology have fine-tuned the process, making it a cornerstone in modern manufacturing.

How Ultrasonic Welding Works:

Ultrasonic welding relies on the principles of high-frequency mechanical vibrations, typically in the ultrasonic range (20 kHz to 70 kHz). The process involves the following steps:

Contact and Compression:

Materials to be welded are brought into contact under pressure.

Ultrasonic Vibration:

An ultrasonic horn connected to a transducer generates high-frequency vibrations.

Heat Generation:

The vibrations generate friction and heat at the weld interface, causing the materials to melt and form a bond.

Solidification:

Once the desired temperature is reached, the vibrations cease, and the materials solidify, creating a strong weld.

Applications in Manufacturing:

Ultrasonic welding finds extensive use in various manufacturing processes, including:

Plastic Welding:

Commonly used in the assembly of plastic components, such as automotive parts, medical devices, and consumer electronics.

Metal Welding:

Applied in the welding of non-ferrous metals like aluminum and copper, providing a clean and precise joining method.

Textile Bonding:

Used in the textile industry for joining fabrics and creating strong, durable seams.

Packaging Industry:

Ideal for sealing and bonding in the packaging of food, pharmaceuticals, and other consumer goods.

Value Proposition of Ultrasonic Welding:

Speed and Efficiency:

Ultrasonic welding is a high-speed process, contributing to increased production efficiency.

Precision and Consistency:

The method ensures precise and consistent welds, reducing the likelihood of defects.

No Consumables:

Unlike traditional welding methods, ultrasonic welding doesn't require consumables such as adhesives or additional materials.

Clean and Environmentally Friendly:

Ultrasonic welding produces minimal waste and is considered an environmentally friendly process.

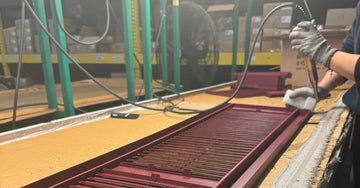

Effectiveness in Vinyl Manufacturing:

In our vinyl manufacturing facility, ultrasonic welding plays a crucial role in joining vinyl components. The technology's effectiveness in creating strong and durable bonds ensures the production of high-quality vinyl products.

Conclusion: Ultrasonic welding has become a cornerstone in modern manufacturing, offering a combination of speed, precision, and efficiency. As industries continue to evolve, the versatility of ultrasonic welding makes it a valuable asset in producing high-quality products across various sectors. Whether in plastic, metal, or textile manufacturing, the impact of ultrasonic welding resonates as a reliable and innovative joining technique.